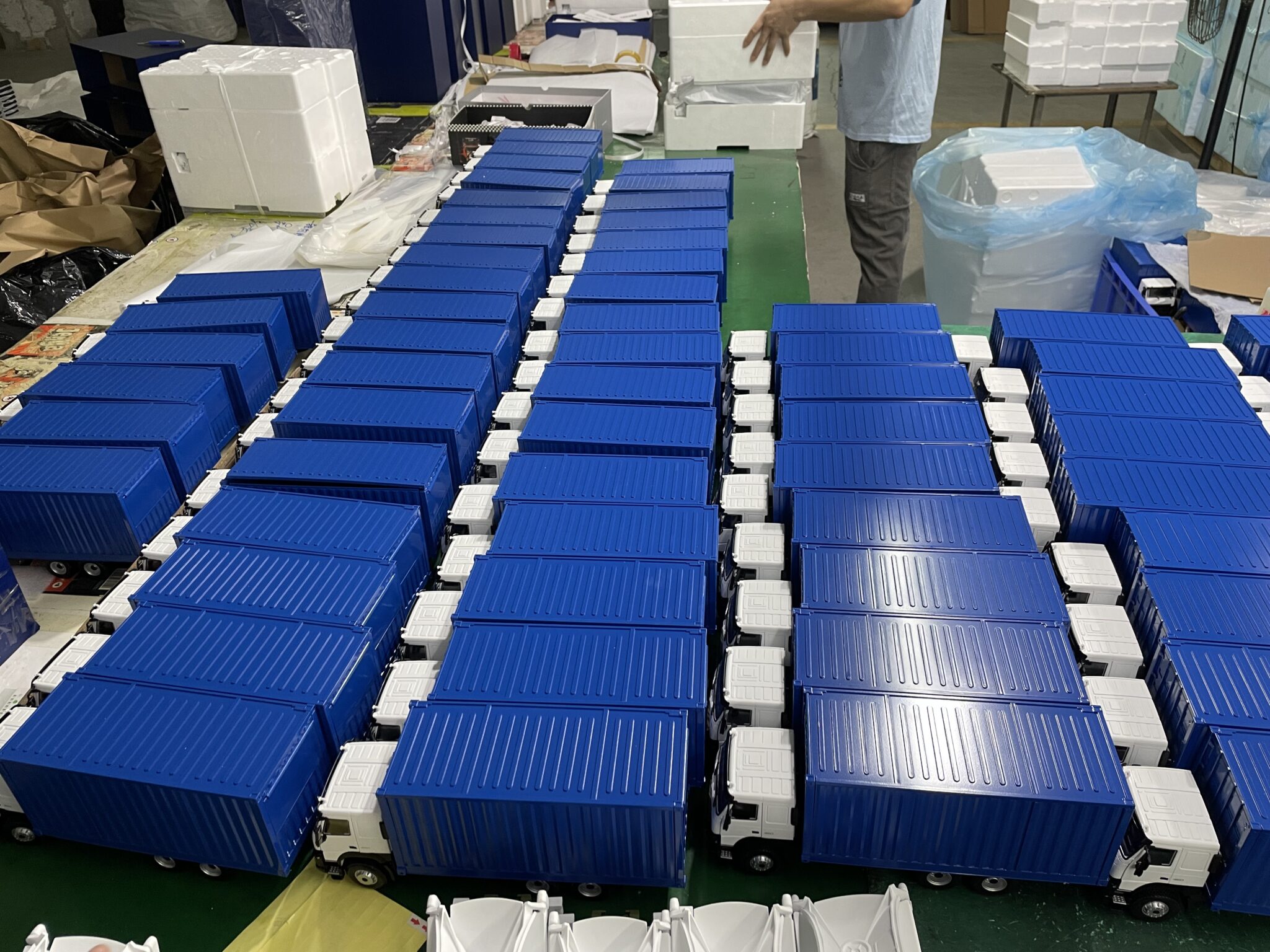

The last step in model production.

Our assembly department is responsible for assembling parts with precision and efficiency, ensuring that each unit meets our stringent quality standards.

There are nearly 180 skilled assembly employees in our assembly dept. and features five dedicated assembly lines. One line specializes in the production of car and bus models, while another focuses on heavy-duty vehicles such as tractors and dump trucks. A third line is dedicated to engineering machinery models, including excavators, concrete pumps, and cranes. Additionally, we have a line for aircraft models. We also operate a dedicated line for urgent orders. This structured approach ensures efficiency and high-quality output in our assembly processes.

Main Procedure

Heat Staking

Screw Fastening

This process involves using a soldering iron to apply controlled heat, which melts and fuses two parts together. The heat staking method ensures a secure bond between components, creating a durable connection that maintains the integrity of the assembled product. This technique is particularly effective for joining plastic or metal parts in a precise and reliable manner.

For components that bear significant force, we secure them using screws to ensure structural integrity and stability. This method provides reliable and durable fastening, particularly for parts that are subjected to stress or frequent movement, thereby enhancing the overall durability of the assembly.

Hot Stamping

Gluing

This process is used to apply chrome edges to glass components. By using a hot stamping machine, the chrome layer from the silver foil is transferred onto the parts at a temperature of approximately 220°C. The high heat and pressure ensure that the chrome adheres smoothly to the surface, creating a sleek, metallic finish on the edges. This technique is critical for achieving high-quality decorative details on glass parts in manufacturing.

The assembly of parts is carried out using high-strength adhesive that is specially formulated to ensure a secure bond between components. This adhesive is selected for its non-whitening properties, meaning it will not leave visible residue or discoloration after curing, preserving the clean aesthetic of the product. The glue’s high viscosity ensures that it holds parts together firmly, providing long-lasting durability, even under stress or environmental factors such as temperature changes or vibrations.

Water Decal Application

Cleaning

The chrome-plated logos on the front and rear of the model are typically created using electroplated water decals. These decals are carefully positioned and applied to ensure they adhere securely and accurately to the correct locations on the model.

After the assembly is complete, the model undergoes a thorough cleaning procedure to remove dust, smudges, excess oil, and other surface contaminants. This step is crucial to ensure that the final product is free from imperfections and maintains its high-quality appearance.

QC Inspection

Secondary cleaning

After the final assembly, our QC carries out inspections based on established acceptance criteria. Only parts that meet the quality standards are approved for packing. Defective items are classified as scrap and handled accordingly.

To ensure the highest quality, all models that have passed inspection undergo a secondary cleaning process. This step removes any remaining dust, debris, or particles that may have accumulated during production or handling.

Packaging

Heat Shrink Wrapping

Once the models have passed the inspection process, they are carefully packaged into custom-designed color boxes, ensuring compliance with specified packaging standards. Each model is secured to prevent movement during transport, maintaining the integrity of the product. The packaging not only serves as a protective barrier but also enhances the product’s presentation, reflecting the quality and craftsmanship of the model.

This process involves applying a heat shrink film to the surface of the pre-packaged color box, tailored to meet specific customer requirements. The heat shrink film provides a protective layer, safeguarding the product from environmental factors, dust, and damage during storage and transportation. This method enhances the overall presentation of the packaging while ensuring product integrity, thereby increasing customer satisfaction.

Crafting Quality, Delivering Excellence!

—Each component is meticulously crafted and assembled to perfection—

©miraunion 2024 All Rights Reserved.