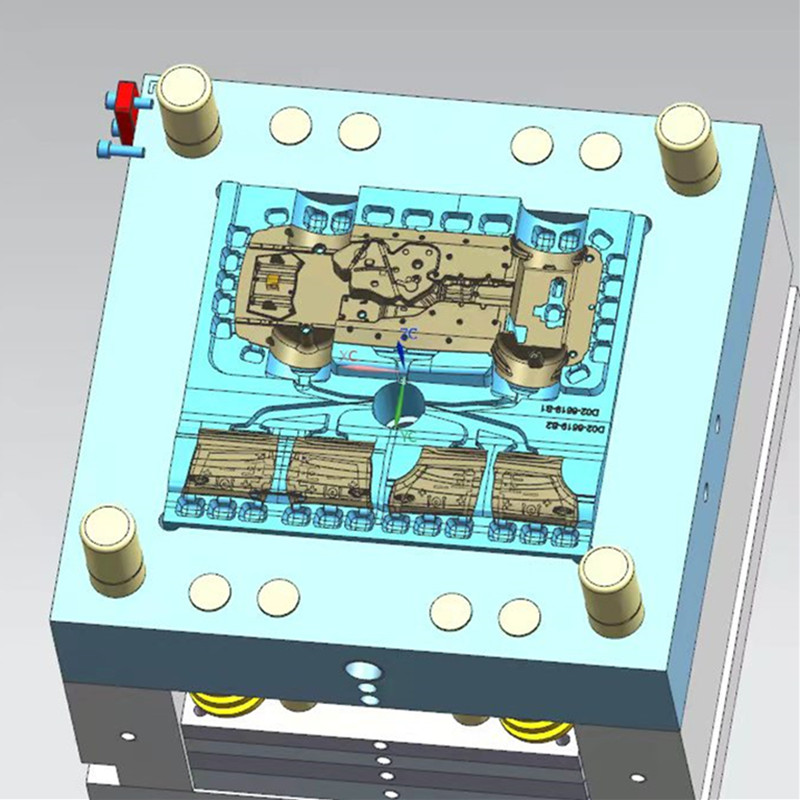

The second phase of model production includes mold design, CNC programming, and a fully computerized workflow, creating a digital production process.In the mold-making process, CNC machines are crucial because they ensure that molds are made with exact measurements, which helps in mass-producing items that are identical in shape and size. The process starts with a 3D model design, which is then converted into CNC programming. The machine uses tools like drills or cutters to carve out the mold from a solid block of material.

Main Duties

- Creating, editing, and optimizing CNC programs.

- Operating computer numerical control machines to produce precision parts and components of moulds.

- Ensuring Quality Control.

- Fully computerized workflow, creating a digital production process.

CNC Programming

CNC Programming is the process of creating code that guides machines to perform specific tasks, such as cutting, drilling, or shaping materials. our programmers write and optimize these codes to ensure machines run efficiently and accurately. Using software like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing), CNC programmers translate 3D models into instructions that the machines can follow. They play a crucial role in making sure that the final product meets design specifications while minimizing waste and improving production speed.

CNC Mold Fashioning

CNC mold fashioning is a key part of the molds manufacturing process. It involves using CNC machines to precisely shape and form molds, which are used to create partsof the molds. These machines follow programmed instructions to cut, carve, and shape materials like metal or plastic with high accuracy.

CNC Maching Center

We currently operate 20 advanced CNC machining centers, 12 of which are high-speed units designed for precision work. These high-speed machines feature spindle speeds of up to 24,000 rpm, enabling them to handle ultra-fine tools with a minimum diameter of just 0.15 mm. They are primarily utilized for intricate copper work and detailed engraving, ensuring exceptional accuracy and craftsmanship.

Monthly output:

Our CNC department has a monthly production capacity of 60 sets of molds. This output is equivalent to producing molds for approximately six different vehicle models each month. This production capability allows us to efficiently meet the needs of various projects while maintaining a consistent focus on quality and precision in mold manufacturing.

Delivering flawless molds for your most demanding projects.

Unlock precision and speed with our state-of-the-art CNC machining centers

© 2022 All Rights Reserved.