Our injection molding department is responsible for producing all plastic components, such as tires, seats, glass, and ABS interior parts. The production process includes material mixing, injection molding, gate trimming, and post-molding cleanup. Once processed, the parts undergo quality inspections before moving to the next production stage. Only the qualified products can flow to the next procedure.

Currently, our department has a daily production capacity of 30,000pcs and a monthly output of 720,000pcs.

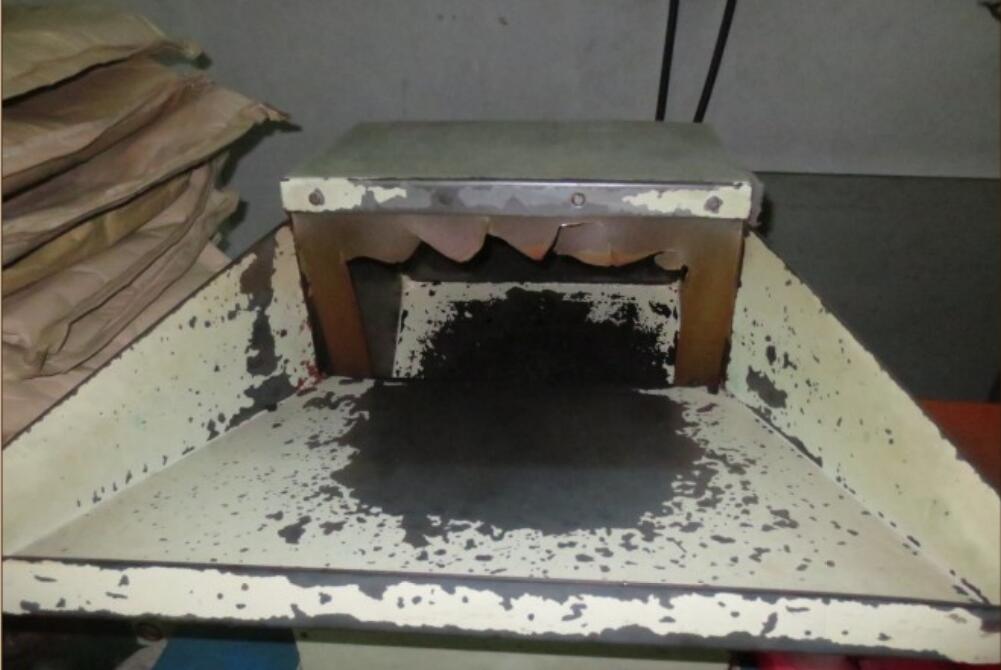

Post-process treatment

Our tooling department currently operate 16 EDM and mirror spark machines, including 3 advanced mirror spark machines that are among the first of their kind in the industry. These high-end machines are primarily used for producing electroplated and transparent parts. Additionally, we have over 50 pieces of equipment, including milling machines, grinding machines, wire-cut EDM machines, and drilling machines. With these resources, our tooling department is capable of producing up to 60 sets of molds per month, equivalent to molds for 6 different car models.

Color Material Mixing

Injection molding production

To ensure the final product matches the required color specifications.

The correct color pigments are added and thoroughly mixed with the base material.

This ensures that the produced parts achieve a uniform and consistent color as per the parts requirements of color.

In the injection molding process, plastic raw materials are heated and sheared by the rotating screw inside the injection molding machine, causing them to melt into a fluid state. The molten material is then injected into a mold by the screw under high pressure at temperatures ranging from 180 to 220°C. After cooling, the material solidifies into the desired plastic part. Different types of plastics require specific adjustments in temperature, pressure, and time parameters to ensure proper molding and part quality.

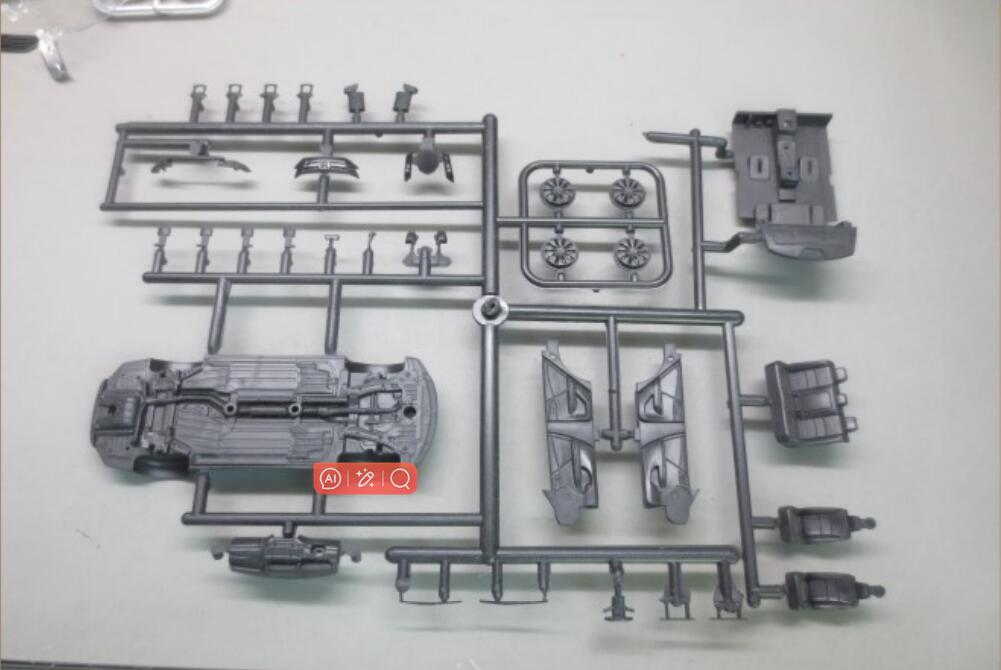

Gate Trimming

Inlet Gate Trimming

A single mold is designed to produce multiple components simultaneously. Once the production process is complete, it is essential to carefully separate the parts from the runner system and organize them according to specified requirements. This step ensures that each component is properly prepared for the next phase of production and meets quality standards.

This process involves using a blade to meticulously remove any burrs from the inlet gate.

By ensuring a clean and precise trim, we enhance the overall quality of the plastic components, facilitating smoother assembly and better fit during subsequent manufacturing stages.

Flocking

Electroplated Chrome Plating

In our production process, we prioritize achieving a high level of realism for the real vehicle, such as the interior seat base and trunk lid. To enhance the authenticity of these parts, we employ techniques like flocking, or use spray painting with specialized faux-fur coatings to achieve a similar effect. This attention to detail not only improves the aesthetic quality of our products but also enhances the overall user experience by providing a more realistic look and feel.

For components that correspond to the chrome plating found on real vehicles, we utilize a chrome plating process followed by an electroplating method to achieve a chrome finish.

This technique not only enhances the aesthetic appeal of the parts but also provides a durable and corrosion-resistant surface, ensuring that the finished products maintain their shine and integrity over time.

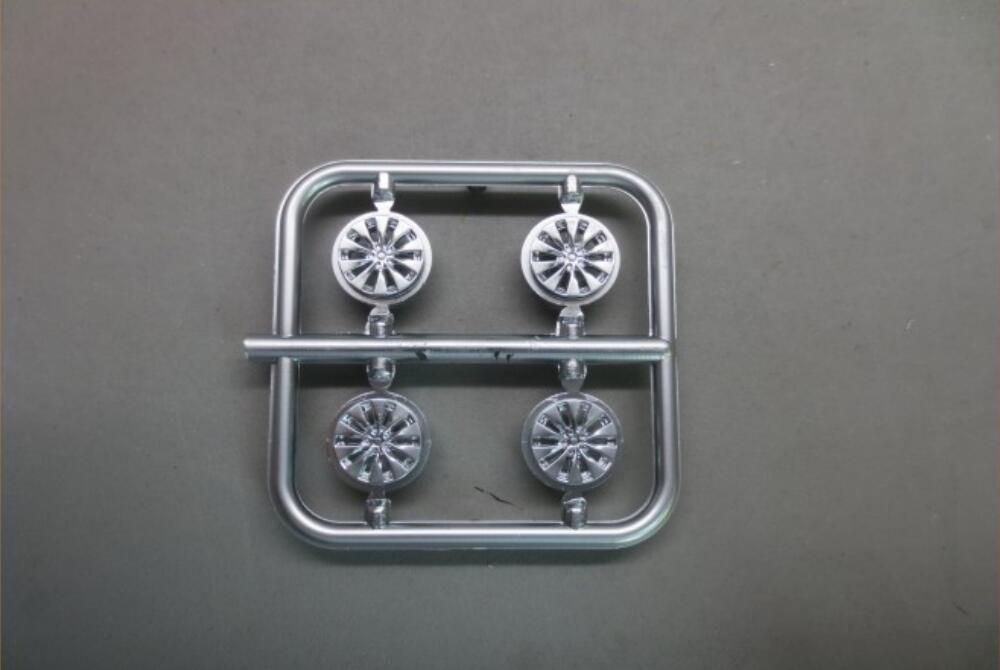

Electroplated Pearl Chrome Finish

Water Transfer Printing

Electroplated pearl chrome is a specialized finish often applied to wheel hubs to enhance their aesthetic appeal and durability. This process involves depositing a thin layer of chrome onto a substrate through electroplating, creating a lustrous, reflective surface that mimics the look of pearl. It helps protect the underlying material from corrosion, wear, and environmental damage, ensuring that wheel hubs maintain their pristine appearance over time. Additionally, this finish contributes to improved performance by reducing friction and enhancing the overall quality of the wheel assembly.

Water transfer printing, also known as hydrographics, is a technique used for applying intricate patterns and textures to parts with complex shapes.

This method is particularly effective for items that require a unique finish, such as wood grain, like cherry wood, and high-tech designs, like carbon fiber. By utilizing water transfer printing, we can achieve a seamless, high-quality aesthetic that enhances the visual appeal of our models while ensuring durability and consistency across various surfaces.

Net Arrangement

First Coating Process

Some plastic components are too small to undergo automated spraying, requiring manual arrangement on a net. This process ensures that these smaller parts are properly positioned on a mesh board, allowing for efficient and effective spraying in the subsequent steps. Proper placement not only optimizes the application of coatings but also helps maintain quality control throughout the production process.

The components are placed in a dust-free environment within a water curtain spray booth for the initial coating.

This controlled setting ensures that the parts receive a uniform and high-quality finish, minimizing the risk of contamination during the spraying process.

Flipping Process

Second Coating Process

During the painting process, both sides of the part need to be coated. After one side is sprayed, the part is carefully flipped to apply paint to the other side. The number of flips required depends on the color and the number of coats needed to achieve the desired finish. This ensures that every part is evenly coated on all surfaces.

The components are placed in a dust-free environment within a water curtain spray booth for the initial coating.

Small-Area Spray Painting

Pad Printing

This technique is used to apply decorative finishes to specific small areas, ensuring precision and detail in the final appearance of the product. It is commonly providing a high-quality decorative touch to products’ surfaces.

Pad printing is a process that uses a silicone pad and a steel plate to transfer decorative designs onto parts or surfaces of diecast scale models. Depending on the complexity and length of the design, this process can involve either single or multiple transfers. Pad printing is commonly used for creating logos and other decorative patterns on a variety of materials.

Screen Printing

Touch-up

For large, flat parts, we utilize screen printing technology to create the necessary decorative surfaces.

This method ensures precise and consistent application of designs or markings across the surface, making it ideal for producing high-quality finished scale models.

For areas that are difficult to reach during spray painting or pad printing, we use a manual touch-up process. Skilled workers carefully apply paint by hand to these sections, adding decorative details. After the touch-up, any excess paint or smudges around the decorations are meticulously wiped away to ensure a clean and polished surface.

Precision, efficiency, and quality

—our injection molding department delivers high-performance plastic components, from tires and seats to ABS interior parts—

© 2024 All Rights Reserved.